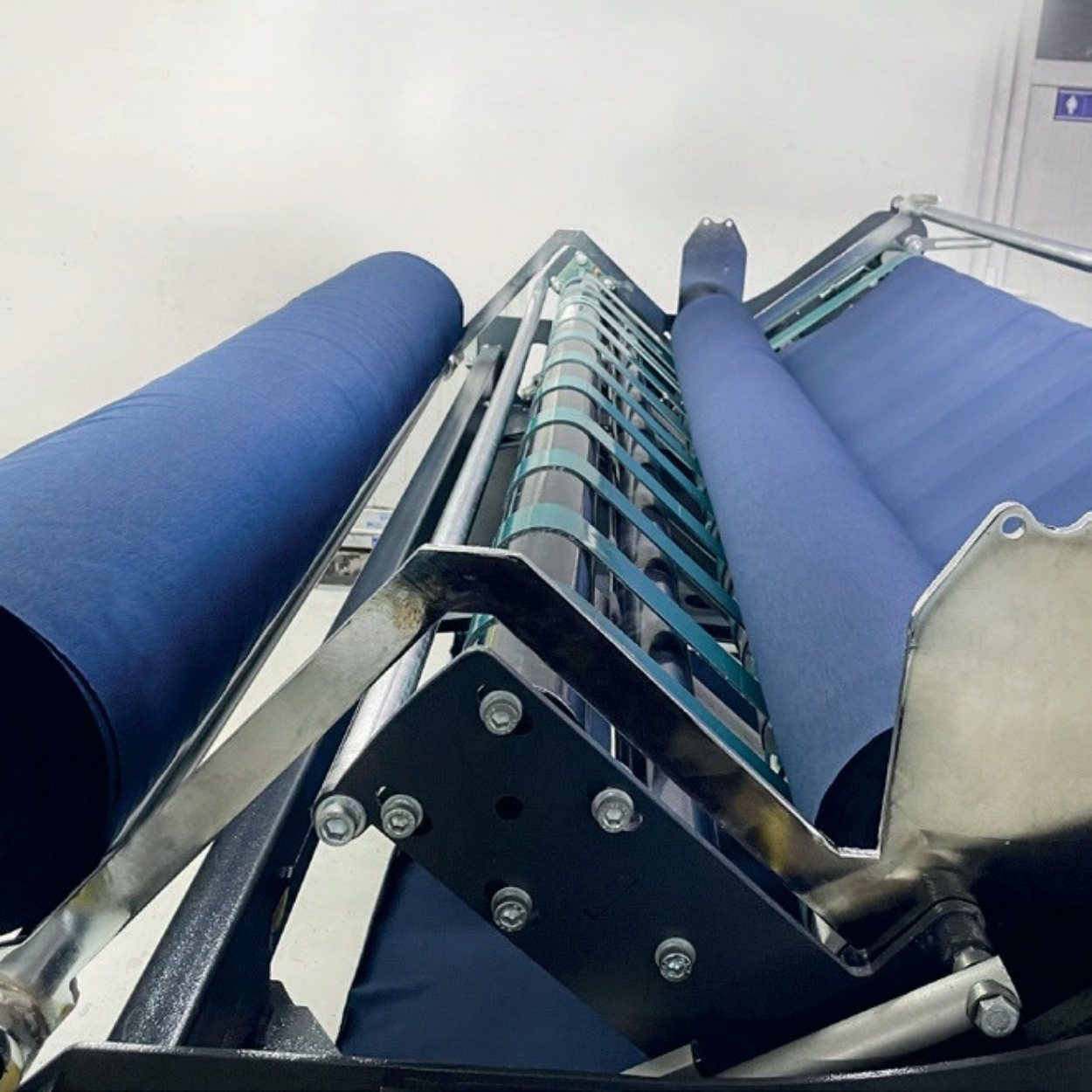

APS 1 JS Fabric Spreading Machine

Product Code: APS1JS

The Alser APS1 JS is a high-performance spreading machine specially designed for heavy fabrics (up to 250 kg). Its key differentiator is its conveyor belt servo motor feeding system, which spreads even the most challenging fabrics without pulling and with full tension control.

It provides maximum efficiency with its high spreading speed, waste-free cutting system, and photocell edge control. Its smart automation features (automatic stop, ply alert) and PLC touchscreen make it easy and safe to use, even in a fast-paced production environment.

It provides maximum efficiency with its high spreading speed, waste-free cutting system, and photocell edge control. Its smart automation features (automatic stop, ply alert) and PLC touchscreen make it easy and safe to use, even in a fast-paced production environment.

Superior Spreading Technology for Heavy and Elastic Fabrics

Superior Spreading Technology for Heavy and Flexible FabricsAlser APS1 JS: Superior Power and Precision for Heavy Fabrics The Alser APS1 JS is an industrial powerhouse specially designed for spreading the most challenging and heavy fabrics. Its robust and ergonomic chassis easily manages impressive roll weights of up to 250 kg, while reaching spreading speeds of up to 105 meters per minute, ensuring no compromise on productivity. It perfectly adapts to every marker with a flexible working width ranging from 160 cm to 220 cm.

Enhanced Traction and Control for Heavy Fabrics The torque and precision required for heavy fabrics are provided by the APS1 JS's conveyor belt servo motor fabric feeding system. This advanced system feeds the fabric with full control, without pulling it. Automatic tension control guarantees that spreading is done at the desired tension, regardless of the material type. It can even spread flexible fabrics precisely without stretching them.

Maximum Efficiency with Smart Automation Efficiency is in this machine's DNA. The waste-free cutting system with automatic cutting adjustment reduces your valuable material costs. Operator intervention is minimized thanks to automatic marker height adjustment and a programmable ply count. Smart sensors automatically stop the machine when the fabric runs out and provide instant alerts when the target ply count is reached or in the event of a potential malfunction.

User-Focused, Safe Design Power is meaningful when combined with control. The PLC system with an easy-to-use touchscreen control panel simplifies the management of the entire operation. It provides full flexibility with one-way and zigzag spreading modes, a speed-adjustable cutting apparatus, and a fabric rewinding feature. Operator safety is maximized with a personnel carrier platform equipped with safety sensors.