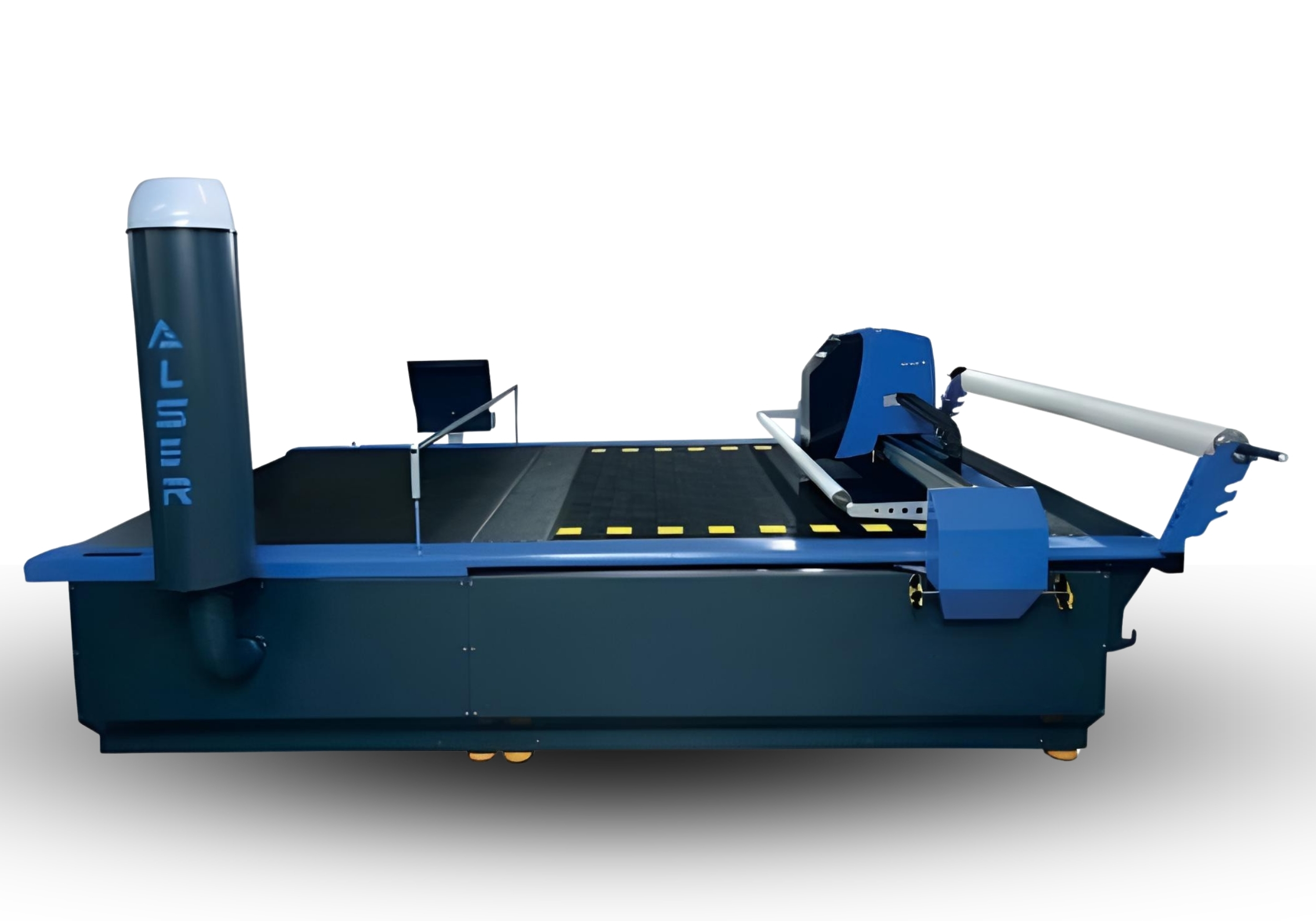

ALCUT 7 Multi-Layer Cutting Machine

Product Code: ALC7

Redefine your production standards. Our new-generation cutting machine combines power and precision with an exceptional 7 cm vacuum cutting capacity and a precise XY transmission system. While smart automation features, such as an automatic knife sharpening and cooling unit, ensure continuous production, its 98% CAD software compatibility offers full flexibility. Thanks to its two-part modular chassis, it is easily transported and quickly installed, optimizing your costs with low energy consumption.

Advanced Cutting Technology

Meet our new-generation cutting machine, designed to take your production line to the pinnacle. Don't just cut—redefine the standards in your industry. Thanks to its high-precision chassis, tackle even the most challenging materials with an exceptional cutting capacity of up to 7 cm under vacuum.This machine is designed to optimize your operations by combining power and smart technology.

Flawless Performance and Superior Precision Get perfect results every time. The powerful and speed-adjustable vacuum pump holds the material steady, while the XY transmission system (gear and rack) offers precise movement capability for many years without deviation. The domestically produced cutting bristles, which stand out with their strength and high friction coefficient, maximize cutting quality.

Powerful Vacuum Pump: Perfect adaptation to different materials thanks to speed adjustment.

Precise XY Transmission: Durable gear and rack system for long-lasting and error-free cuts.

Film Sealing Support: The film sealing (mulching) feature for cut fabrics preserves vacuum suction, preventing shifting.

Uninterrupted Production with Smart Automation Minimize downtime. The Automatic Knife Sharpening Module ensures your knife always stays sharp with its long-lasting sharpening stone. The innovative cooling unit prevents the knife from sticking to the cutting materials, guaranteeing a clean and smooth cut even on the stickiest materials.

Automatic Knife Sharpening: Continuous operation and minimal maintenance needs.

Knife Cooling Unit: Prevents material adhesion, reduces waste rate.

Automatic Sensor System: Sensors developed for the secondary film cover detect and reduce air leakage during cutting, maximizing vacuum efficiency.

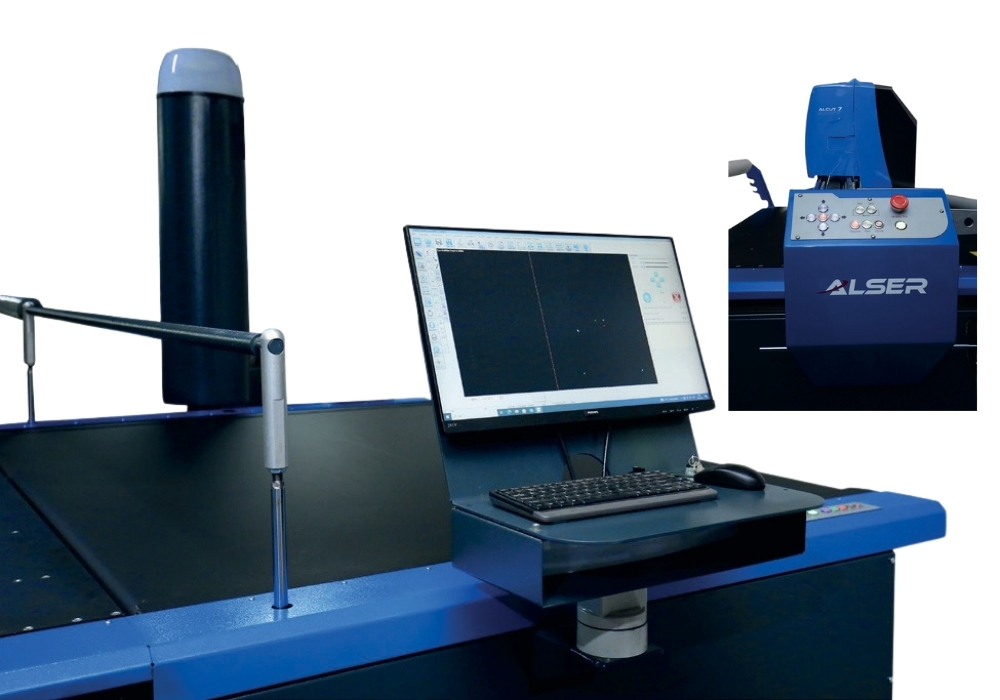

Full Control and Unlimited Flexibility Streamline your workflow. The intuitive Control Screen and an LCD monitor equipped with the familiar Windows operating system give your operators full command over the machine. Managing the cutting process and clearly checking the results has never been easier.

Universal Compatibility: Our control system is 98% compatible with fabric CAD software and seamlessly accepts different file formats such as PLT, DXF, CUT, and TAC.

Customizable Drilling Module: In addition to standard 1.5-20mm diameter options, increase your production flexibility with a customizable number and size of modules according to your needs.

Smart Design: Safe, Efficient, and Modular Not just a powerful, but also a smart investment. A mechanical safety barrier ensures maximum job safety for your operators. Achieve high performance with low energy costs, thanks to efficient energy consumption between 16-25 kW.

One of our biggest innovations, the two-part modular chassis structure, redefines logistics and installation processes. Thanks to this easily transportable structure, the assembly process is completed in record time, giving you flexibility in your production area and perfectly optimizing space utilization.